Screen Panel Anomaly

Highlights

Results

Details

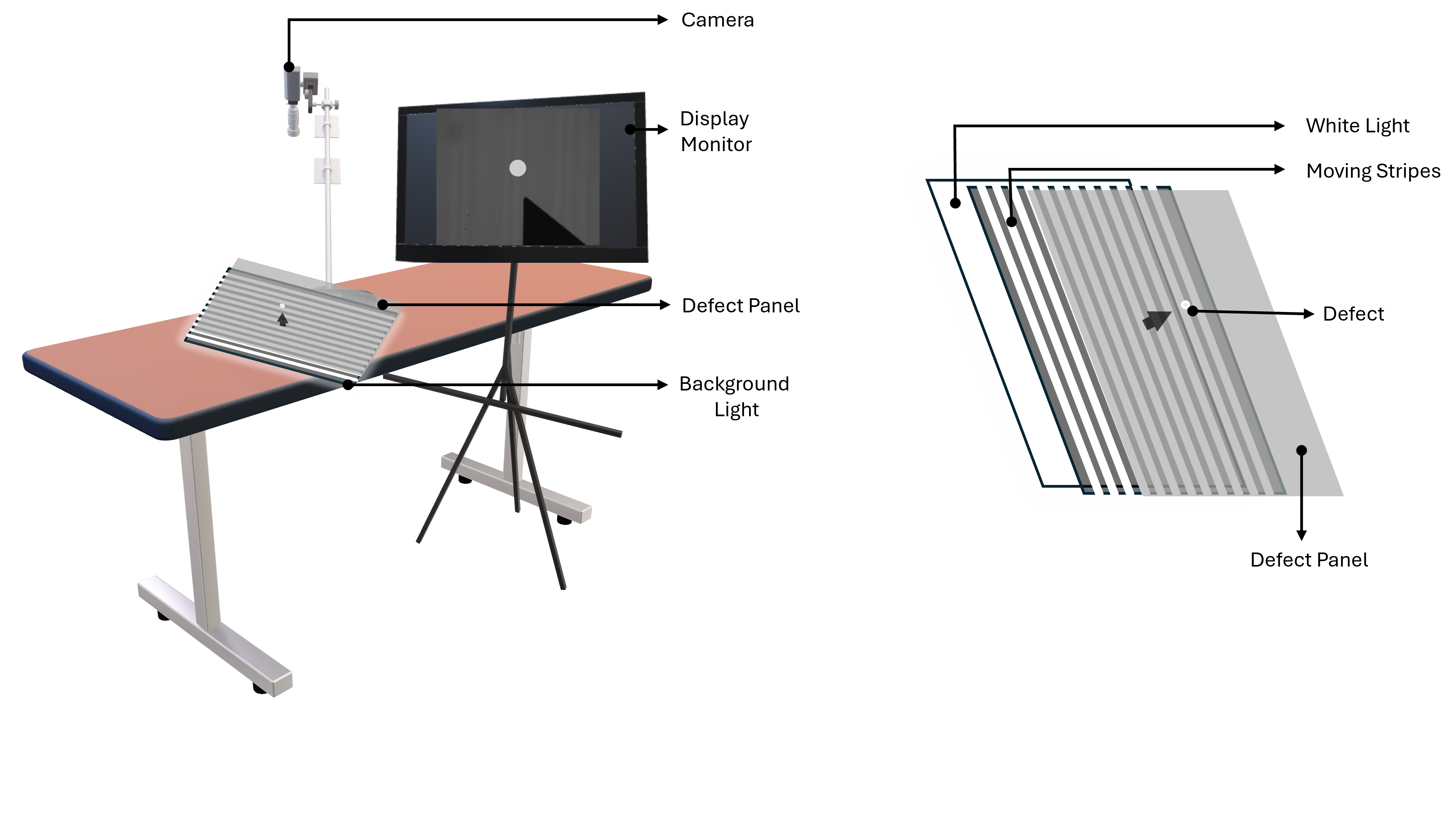

Automated detection of subtle surface anomalies on industrial display panels using structured illumination and deep learning.

Problem

Surface defects on display panels are often extremely small, low-contrast, and visually similar to background noise, making manual inspection unreliable and time-consuming.

The goal of this project was to develop an automated pipeline capable of detecting and localizing microscopic panel defects under controlled illumination conditions.

Key constraints included:

- Defects occupying only a few pixels

- Strong background patterns (moving stripes, lighting artifacts)

- Severe class imbalance between defective and non-defective regions

- Requirement for high precision to avoid false alarms in production

Approach

Data

- Custom image acquisition setup using:

- Fixed camera

- Display monitor with structured illumination (white light + moving stripes)

- Controlled background lighting

- Multiple captures of the same panel were merged to enhance defect visibility

- Two defect classes annotated using bounding boxes

- Dataset characterized by extreme foreground sparsity

Model

- YOLO-based object detection framework for real-time defect localization

- Two-class detection setup

- SAM explored for post-processing and region refinement

- Detection focused on small-object sensitivity rather than large contextual cues

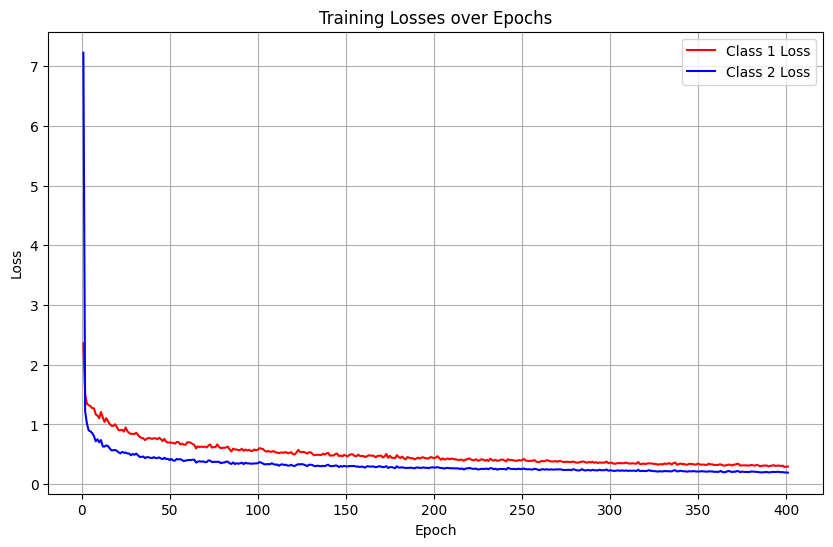

Training

- Long-horizon training (≈400 epochs) to stabilize learning under class imbalance

- Class-wise loss monitoring to ensure balanced convergence

- Extensive filtering of false positives during early epochs

- Careful threshold tuning for confidence-based suppression

Evaluation

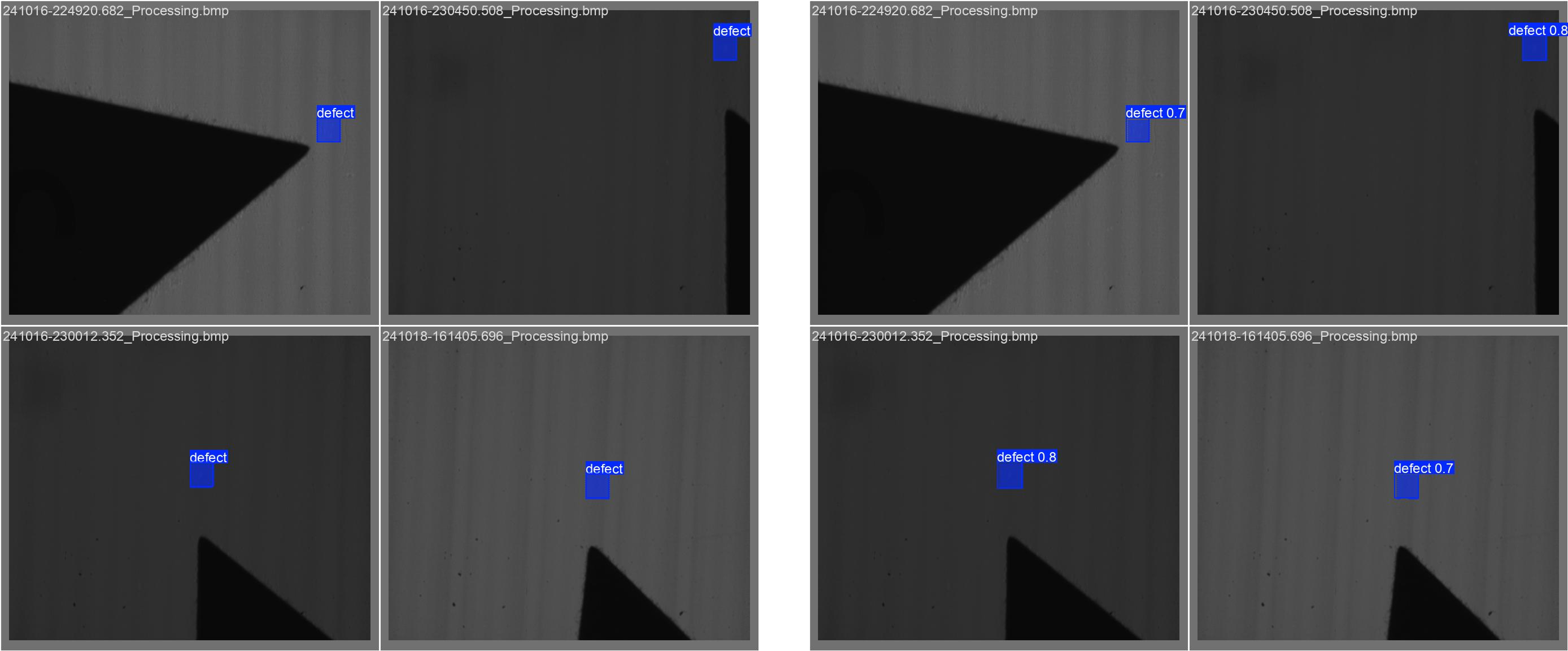

- Precision and recall tracked independently for each defect class

- Qualitative inspection used as a primary validation signal due to rarity of defects

- Final models achieved stable high precision and recall after convergence

Post-evaluation detection results on unseen panels. The model localizes subtle defects with high confidence while suppressing illumination-induced artifacts.

Notes & Lessons Learned

- Structured illumination is critical: raw images without stripe modulation hide most defects

- Merging multiple frames significantly improves defect visibility

- Small-object detection is more sensitive to preprocessing than model choice

- Early training instability is expected due to extreme imbalance and sparse positives

- Classical image processing remains valuable as a complement to deep learning in industrial settings

This project emphasized robust deployment-oriented design, balancing detection accuracy with false-positive control under real manufacturing constraints.